Q: Are you a factory or trading company? A:We are the manufacturer Q: Can you provide the free samples? A:No sample fee for regular products Q: How does your factory do regarding quality control? A: 100% raw material inspection and 10% Finished product inspection. Q: Do you have a minimum order quantity? A: Our MOQ is 50 PCS for very item Q: Can you OEM or ODM? A:15-25 days after receiving the deposit payment .

Q: Are you a factory or trading company? A:We are the manufacturer Q: Can you provide the free samples? A:No sample fee for regular products Q: How does your factory do regarding quality control? A: 100% raw material inspection and 10% Finished product inspection. Q: Do you have a minimum order quantity? A: Our MOQ is 50 PCS for very item Q: Can you OEM or ODM? A:15-25 days after receiving the deposit payment . | Steel bar cutter / steel cutting machine | |||

| Model | GQ50E | GQ50A | GQ50D |

| Cutting rebar Dia (Plain Carbon Steel) | Ф6-42mm | Ф6-45mm | Ф6-42mm |

| Ⅱgrade screw thread rebar Dia: | Ф6-32mm | Ф6-36mm | Ф6-32mm |

| Flat steel max. diameter: | 80×18mm | 80×18mm | 80×18mm |

| Cutting square steel max. spec(Q235A) | 40×40mm | 40×40mm | 40×40mm |

| Angle steel max. spec : | 63x63mm | 63x63mm | 63x63mm |

| Cutting quantity: | 28t/min | 28t/min | 28t/min |

| Motor spec: model: | Y112M-2 4KW | Y112M-2 4KW | 12.5HP Diesel Engine |

| Voltage / speed | 380V 2800rpm | 380V 2800rpm | Diesel Engine |

| Net weight: | 485kgs | 509kgs | 619kgs |

| Gross weight: | 515kgs | 534kgs | 660kgs |

| Packing size: | 1450*600*1020mm | 1500*600*1020mm | |

Cutting Ability

Recommendation for piece number of simultaneously cutting off steel bars with diameters smaller than φ22mm

| Diameter of steel bar (mm) | 4~8 | 10~13 | 14~18 | 19~22 | More than 22 |

| Cutting off piece number each time | 6 | 5 | 3 | 2 | 1 |

| GQ40 | 6 | 5 | 3 | 2 | 1 |

| GQ50 | 8 | 5 | 4 | 3 | 2 |

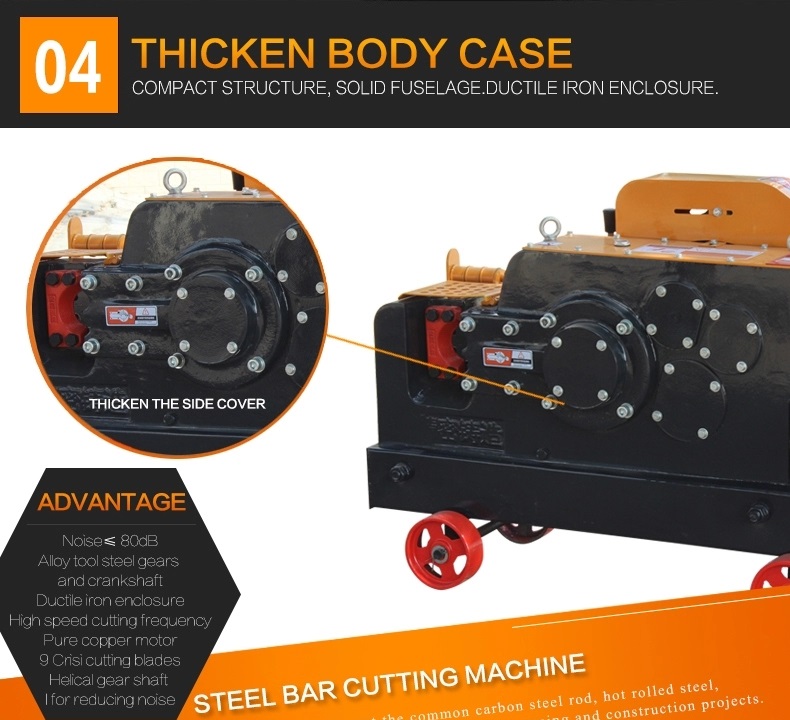

GEAR: cast steel CRANKSHAFT: cast steel SHAFT 1, SHAFT 2 and SHAFT 3: C45 steel CONNECTION ROD: cast steel BLADE: cast steel EXTERNAL CASE: Ductile Iron *All the main components undergone the required heat treatment (quenching, tempering or high frequency).

GEAR: cast steel CRANKSHAFT: cast steel SHAFT 1, SHAFT 2 and SHAFT 3: C45 steel CONNECTION ROD: cast steel BLADE: cast steel EXTERNAL CASE: Ductile Iron *All the main components undergone the required heat treatment (quenching, tempering or high frequency).